In the industrial revolution that dominates production today, the aim is to obtain a large number of the same product in a short time at lower cost. In order to achieve this goal, industrialization must begin by starting mass production. One of the significant steps of industrialization is that production is carried out in factories by machines as much as possible. The need for both the machines having a durable material and the factories with large openings and widths where mass production can be carried out, led to important steps in the steel production process. Thus, steel construction projects have become a preferred constrution type in modern buildings, social centers, commercial buildings, and therefore in our living space. In this article, you will have the answer of the question: what is steel and its features?

Steel is the alloy that results from the combination of iron with some carbon. In addition to carbon, elements such as sulfur, chromium, phosphorus, nickel and magnesium can be found in certain proportions among the raw materials of steel. Thus, steel forms with desired properties can be produced. At the same time, project-specific steel forms can be obtained by using different molds for casting.

The Major Applications of Steel

Since alloys with different properties can be obtained by adding the raw materials of steel in different proportions, the usage area of steel is quite wide. It is used as inox (stainless steel) technology for the kitchen utensils and in cooking pots. Steel is also used in our personal electronic devices such as computers, phones and tablets. It is observed that another important area of use is the automotive industry. It is aimed to ensure driving safety by using thin but high-strength material to reduce vehicle weight. Finally, structural steel, which is the main subject of this article, is used as bearing elements in construction.

The Iron Before Steel

Iron element was used as a building material before steel was produced. Bridges were first started to be built using iron among engineering structures. It was used as cast iron, and was seen in Coalbrookdale Bridge (The Iron Bridge), which has an arch span of 30 meters, built by Abraham Darby III in England between 1777 and 1779. Cast iron works very strongly under pressure. However, it performs less than wrought iron and steel because of its brittleness and low tensile strength under tensile forces and bending moments. For these reasons, Coalbrookdale Bridge was built as an arch bridge. While railway bridges were preferred as girder bridges in England in the 1830s, cast iron was used as a building material. At that time, most of the bridges were demolished, because of being unable to resist the bending moment and tensile force caused by the excessive loading in the middle of the beams, and most were rebuilt using wrought iron.

Wrought Iron

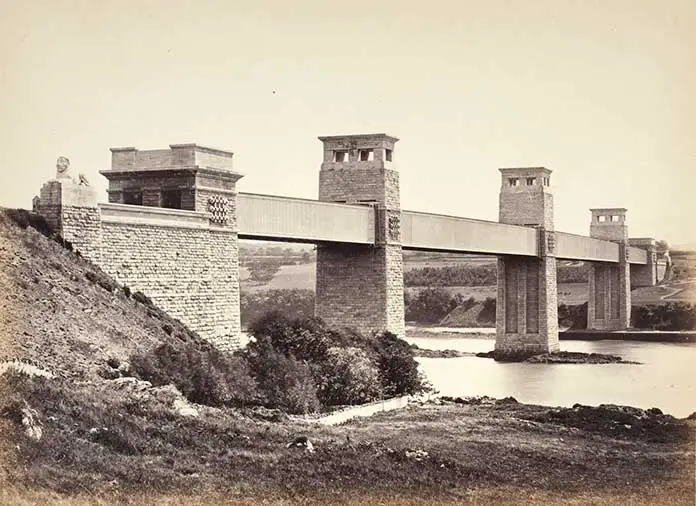

In the 1840s, wrought iron replaced cast iron. When we compare wrought iron and cast iron, the proportion of carbon in the alloy is less in wrought iron. In this way, a material with a more ductile structure was obtained. The bending strength and tensile strength of wrought iron were higher than that of cast iron. One of the earliest examples is the 140-meter-span Britannia Bridge, built in North Wales between 1846-50, resembling rectangular boxes.

The reason why it is called wrought iron is that the iron is processed by pounding with hammers after it is heated enough to take the form of molten slag in the fire. The appearance of slag gives the material a fibrous structure, thus protecting the iron from corrosion. Then the forged iron is suddenly cooled with water and becomes hard. Two types of iron, which were the most important construction materials in the past, are not used in the production of bearing elements buildings today. Because these materials have been replaced by steel.

The issue to be considered here is the use of iron in bridge constructions. It is seen that many bridges were built especially in England. Furthermore, England dominated the iron and steel market in the 18th and 19th centuries. These bridge constructions also include the bridges made for the railway. In addition, the first iron rail was used in a mine in England in 1738. The rolling of the rails used in the railroad started in 1820. The rolling process is the shaping of the steel by passing between the two rollers. Thus, in the 1870s, I-profiles started to be produced.

Structural Steel and Its Features

Steel is formed by combining more than one element homogeneously. Therefore, the mechanical properties are the same in every direction of a steel element. The tensile strength and compressive strength of the steel are equal to each other when the steel element is not buckled and yielded. This means that the element has not been exposed to a load more than its strength. It ensures that the structure does not collapse as brittle. It collapses showing great deformation when exposed to large loads. For this reason, unlike concrete, it is a ductile material. It has a high modulus of elasticity. Since steel profiles for columns and beams of structures are produced in factories, the margin of error is low, so smaller coefficients are used in static calculations compared to reinforced concrete.

Advantages of Steel

- Steel building materials are more durable than concrete materials. One of the main reasons for this situation is the cracking of the concrete under tensile forces while the pressure forces occurring in the building can be absorbed by the concrete. For this reason, steel reinforcements are used together with concrete to meet the tensile forces. You can find an article about reinforced concrete here.

- Construction time of steel structures is shorter than concrete structures. This results in lower labor costs and lower total costs.

- In systems using steel construction, the dimensions of the columns of the building are smaller. Therefore, it leads to an increase in the area used in the building.

- Steel is a recyclable material, it can be reused by being 100% recycled. Likewise, the frames that are connected to each other by bolts can be removed, moved and installed elsewhere.

- Steel structures are lighter in weight than reinforced concrete structures. The reduction of the load to be transported through the foundation allows the building to be built at a lower cost.

- Additional expansion in steel structures can be made when desired, because structural elements can be changed and installed easily.

- The high modulus of elasticity ensures appropriate results in cases where the bending moment to be carried.

Disadvantages of Steel

- The first disadvantage can be said that steel is an expensive material.

- Although it is an easily replaceable and portable material, its maintenance costs are also high. It is galvanized and paints are used to protect against effects such as corrosion and decay.

- Although it is not a flammable substance, its strength and elasticity modulus decrease due to increased heat. At the same time, it is seen that steel is less durable when compared to concrete in terms of fire resistance.

- The joining of columns, beams and connections in steel structures is done by welding or bolts. It requires skilled labor especially for welding.

- Another disadvantage is that an undesirable situation called fatigue occurs in steel structure elements under continuous and repeated loads. Especially when the ropes of the bridges are considered, the ropes that are constantly stretched and released due to the movement of the vehicles may break after a certain period of time. For this reason, it is checked and changed when necessary.

Interesting Steel Constructions in History

1.Home Insurance Company Building

Architect : William Le Baron Jenney

Location : Chicago, USA

Construction Year : 1884

The Home Insurance Company Building is known as the first steel-framed multi-storey building.

2.Eiffel Tower

Architect : Stephen Sauvestre

Location : Paris, France

Construction Year : 1889

The Eiffel Tower is not a steel structure, it was built using wrought iron. Approximately 18 thousand pieces of iron piece elements were used. 2.5 million rivets were used to join iron parts. Although it was exposed to the reaction of the public and artists at first, it is the most preferred building by visitors and tourists as the pupil of Paris.

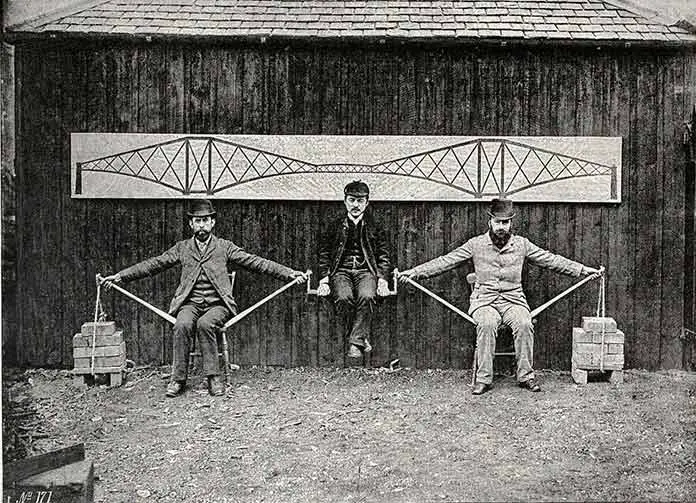

3.Forth Bridge

Designer : Sir John Fowler

Location : Firth of Forth, Scotland

Construction Year : 1890

Approximately 200 trains per day pass through the Forth Bridge, one of the bridges that are still in use today. When it was opened in 1890, it was the longest bridge in the world with a span of 541 meters. The striking feature of the bridge is that it is a cantilever beam bridge.

4.Heydar Aliyev Cultural Center

Architect : Zaha Hadid

Location : Baku, Azerbaijan

Construction Year : 2012

Heydar Aliyev Center consists of a combination of reinforced concrete bearing system and steel space frame skeleton system. The bearing elements are not only reinforced concrete structures, but also the shell formed with the steel space frame system surrounding the building also has a bearing feature. Thus, long spans were easily passed. You can find our article about the architect of this magnificent building, Zaha Hadid, here.